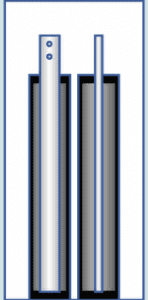

Dual Electrode Technology

consist one Primary Earthing Dual Electrode Technology known as Inner Electrode and other Secondary Earthing Electrode known as Outer Electrode. Hot Dip Galvanized Iron Steel Pipe or Copper Bonded Mild steel Pipe is used as Outer Electrode and Hot Dip Galvanized Iron Steel Strip or Copper Bonded Mild Steel Strip is used as Inner Electrode. Inner Electrode is inserted inside the Outer electrode to the full length from top to bottom.

consist one Primary Earthing Dual Electrode Technology known as Inner Electrode and other Secondary Earthing Electrode known as Outer Electrode. Hot Dip Galvanized Iron Steel Pipe or Copper Bonded Mild steel Pipe is used as Outer Electrode and Hot Dip Galvanized Iron Steel Strip or Copper Bonded Mild Steel Strip is used as Inner Electrode. Inner Electrode is inserted inside the Outer electrode to the full length from top to bottom.

Special highly conductive and non corrosive material is pressurized filled between the Outer and Inner Electrode which safeguard the Electrode getting corrode over a long period of time under the soil. Thus even if the Outer Electrode get corrodes after several years, Inner Electrode remains intact which increases the life and reliability of Earthing System. The Outer Pipe used is of ISI marked standard quality GI Pipe which increase the life of Earthing System.Copper Bonded Earth Electrode are made by carrying out process of high quality molecularly bonding pure electrolytic copper (99.9%) bonding on ISI marked low carbon mild steel pipe.

consist one

consist one  E Link manufacture copper bonded rod /coated solid ground rods in different sizes. These earth / ground rods are made from low carbon steel core having high tensile strength. High quality 99.98 % pure electrolytic copper is molecularly bonded through latest generation electrolytic process. The standard copper coating thickness of 250 micron makes rod suitable for better conductivity and better resistance to corrosion.

E Link manufacture copper bonded rod /coated solid ground rods in different sizes. These earth / ground rods are made from low carbon steel core having high tensile strength. High quality 99.98 % pure electrolytic copper is molecularly bonded through latest generation electrolytic process. The standard copper coating thickness of 250 micron makes rod suitable for better conductivity and better resistance to corrosion.